HOW?

-

Metallurgy expertise

Choosing and advicing the right alloy,

depending on your constraints

(resistance, temperature, environment,...) -

Flexible planning

Strong reactivity.

-

Total traceability

From material supply to finished products.

-

Supply quality

Each material we buy is quality controlled, if needed via retesting.

-

Available stock

-

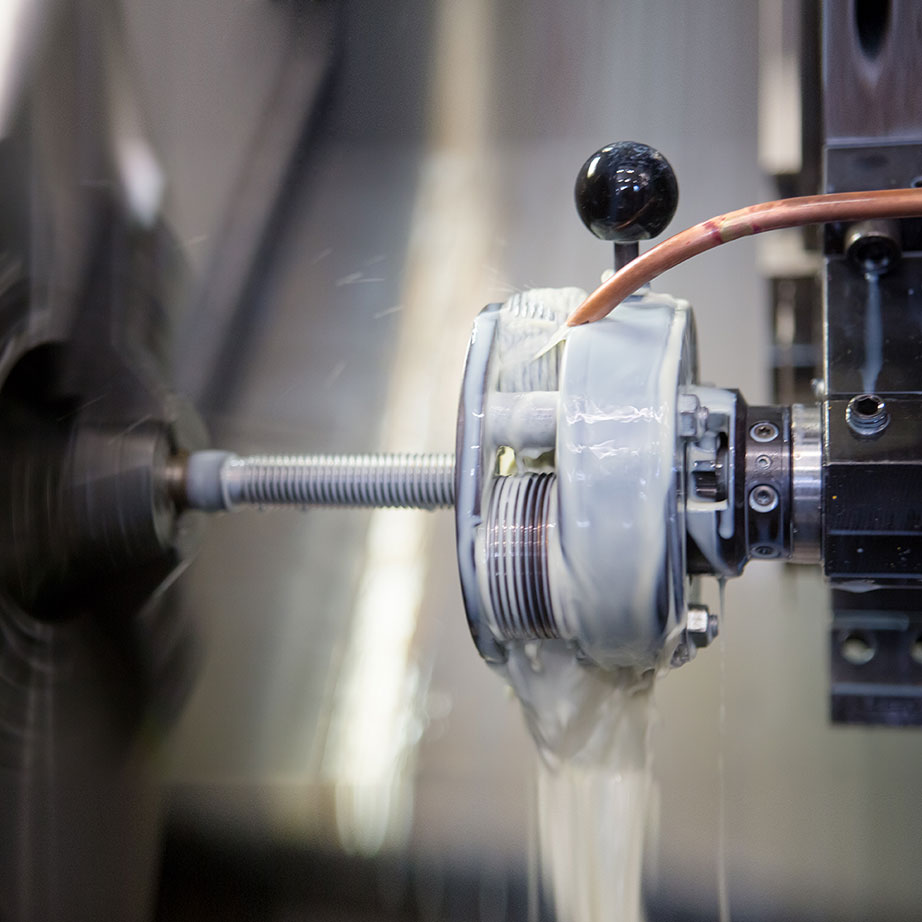

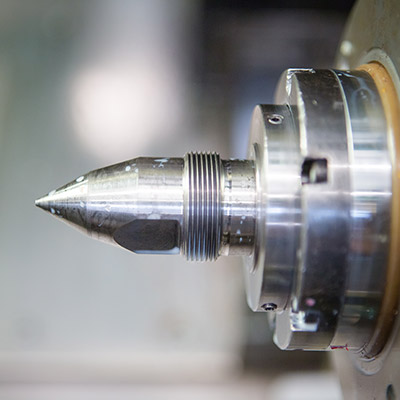

Wide range of capabilities

Thanks to an extended machine park.

-

Repair-transform-rework

Possibility to repair-transform-rework existing parts.

-

production according ASME III standards

-

Power plants

Strategic partner of Electrabel (GDF-Suez Group) for production and quality testing of parts used in power plants.